AXIOME, a new additive technology

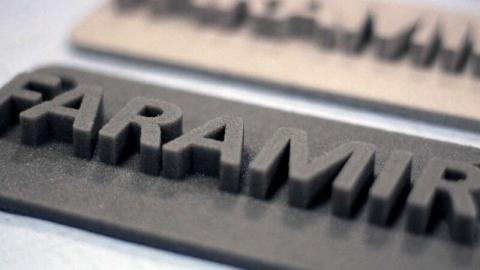

Hardening a sand castle. This is FARAMIR principle (for Rapid Mineral Resin Additive Manufacturing). This collaborative project, costing €1.5 million, is led by the IRT Jules Verne and the Nantes-based SME LOIRETECH, a specialist in tool systems (14 million euros in turnover in 2018, 140 employees). The robotician AXIOME is also part of the adventure. The project gives rise to a new process, based on the hybridization of mineral additive manufacturing and vacuum impregnation of 3D preforms. The objective is to obtain tools with characteristics equivalent to those of aluminium. The principle consists in printing a preform in a mineral material, then injecting resin into it to make it compact and solid, like a kind of ceramic.

The technology combines the freedom of design of 3D printing on complex geometries and the contribution of mechanical strength with polymer resin. "We had two challenges to meet, namely the need to produce large, precise tools in a short time and mechanical strength," explains Marc MORET, CEO of LOIRETECH. In January, a Voxeljet VX200 printer manufactured the first resin-impregnated 3D test parts in the Jules Verne IRT. The next step is to set up a large machine for preforms of 1 meter long. The equipment will then be transferred to the new LOIRETECH plant to enter the industrial phase. It will be made possible to create a tool system of control, assembly and routing for automotive and aeronautical parts.

EMMANUEL GUIMARD – L’usine nouvelle Magazine N°3609