NON DESTRUCTIVE TESTING MACHINES

THERMOGRAPHy

INSPECTION

ULTRASONIC

TESTING

terahertz

control

control by shearography

Non Destructive Testing (NDT) is a method of detecting anomalies in the material without altering it, which determines whether the parts tested comply with the end customer's specification. AXIOME can integrate different NDT processes such as Ultrasonic Testing, Thermography, Terahertz control or Shearography. AXIOME partners with the best specialists in these processes to offer compelete solutions to its customers.

There are several applications and these processes can detect for example:

- Heterogeneity

- Lack of material

- Coves

- Inclusions

- Delaminations

- Damage by impact

- Corrosion

- Water trapped

- Porosities

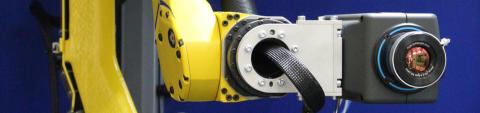

The integration of some NDT processes is based on the use of 2 robots working in synchronized mode, with a transmitter and a receiver. AXIOME designs cells that can work in "carried parts" - the robot carries the part - or in fixed parts and carried tools. For large parts AXIOME uses external axes such as the linear rail or rotary table. The implementation of NDT with a robot makes it possible to control the part, but also to locate the defects and map them, or even to signal their positions for a restart.

NDT applications

Robotic skills and expertise

Robots syncHRONISATION

BENEFITS OF NDT

- Fast

- No contact

- Complex geometries

- Large dimensions

- Repeatable

WHY AUTOMATE NDT?

- Tasks are repetitive

- The high speed of production requires that cycle times are respected

- The diversity of the parts

- The complex shapes of the parts require 3D tool positioning in 6 axes (XYZ + orientations)

- High repeatability of the treatment